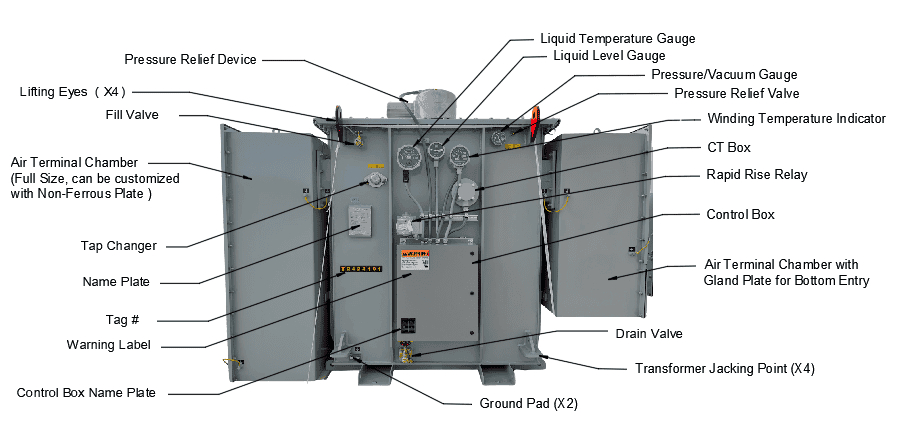

An overview of the Key Components of a Substation Transformer

Substation transformers play a critical role in electrical networks, providing reliable voltage regulation and safe power delivery. Unlike smaller pad-mounted units, substation transformers are typically equipped with additional monitoring devices, protective relays, and control systems to ensure long-term performance and safety.

This article provides an overview of the key substation transformer components that support safe, efficient, and reliable operation.

Key Components of a Substation Transformer

Liquid Level Indicator:

A liquid level indicator ensures that the insulating oil—responsible for cooling and electrical insulation—is maintained at the correct level. Modern indicators feature a clear dial or sight gauge and may include alarm contacts that alert operators to abnormal high or low oil levels. Maintaining proper oil levels is essential for avoiding overheating and insulation breakdown.

Pressure/Vacuum Gauge:

The internal oil and gas volume of a transformer expands and contracts with load and ambient temperature variations. A pressure/vacuum gauge monitors the pressure inside the sealed tank relative to atmospheric pressure. This device helps prevent moisture and air ingress, both of which can compromise insulation performance and reduce transformer life.

Liquid Temperature Indicator (LTI):

- High oil temperature can indicate overloads, cooling system failures, or developing internal faults.

- Many LTIs include alarm/trip contacts that activate cooling fans or pumps when preset temperature limits are exceeded.

Winding Temperature Indicator (WTI):

The WTI measures winding temperatures, which are critical for assessing insulation stress and preventing failure. Like the LTI, it can activate alarms or auxiliary cooling when temperatures rise beyond safe levels.

Modern WTIs are often integrated with digital monitoring systems and can communicate with SCADA or condition-monitoring platforms for real-time oversight.

Sudden Pressure Relay (SPR)

A sudden increase in internal gas pressure can signal an incipient fault, such as arcing, short circuits, or insulation breakdown. The sudden pressure relay detects these changes within fractions of a second and provides both alarm and trip functions. This early-warning device can prevent catastrophic failures by disconnecting the transformer from service before serious damage occurs.

Pressure Relief Device (PRD):

Mounted on the top of the transformer tank, the PRD provides a controlled release of internal overpressure caused by abnormal operating conditions. A deflector cap directs hot gases and oil safely away from nearby equipment and personnel, ensuring operational safety and preventing tank rupture.

Control Box / Control Cabinet:

The control box houses protective relays, monitoring instruments, and auxiliary control circuits within a weatherproof enclosure. It provides local and remote access for operators and integrates with SCADA or smart grid systems. The control box also manages cooling systems, automatically activating fans or pumps based on temperature readings.

Tap Changer:

Load and system variations can cause voltage fluctuations on the network. A tap changer adjusts the transformer’s effective turns ratio to stabilize output voltage:

Off-Load Tap Changer (OLTC): Requires de-energization before adjustment.

On-Load Tap Changer (OLTC): Allows voltage regulation while the transformer remains in service.

Tap changers are essential for maintaining stable voltage levels in dynamic transmission and distribution environments.

Conclusion

Understanding these core components is essential for engineers, operators, and maintenance teams responsible for substation transformers. Each device contributes to safety, reliability, and efficiency, ensuring continuous power supply for industrial and utility networks.

Resources and technical references for this article were adapted from ETAC, a trusted provider of electrical equipment solutions.